Diesels Need Love Too

Our DH5 locomotive has received a fully repaired transoil/water cooler and a newly reconditioned transmission. The latter was sent from Voith Turbo in Queensland and was fitted in record time,…

Read MoreNEW WHEEL PRESS ARRIVES

With the ever-diminishing availability of external engineering or rail workshops to provide PBR services, it was decided and approved that the PBR Workshops should tool up for future wheel operations.…

Read MoreHEAVY MACHINING IN PROGRESS

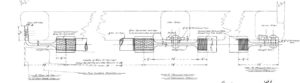

Currently the workshops are preparing the machined parts for 6A’s wheel sets ahead of assembling at Inver Engineering in Altona. With all current wheel sets in the NA fleet comprising…

Read MoreOn Track with 6A – Progress Report

The 6A NA Class locomotive rebuild, supported by the Victorian Government Living Heritage Grant Program and with Puffing Billy Railway (PBR) Major Rebuild Funding, is progressing. With the recent delivery…

Read MoreReturn Of The Dangling Legs – Part 1

Perhaps one of the most iconic experiences one can have on a heritage railway world-wide is that which can be found at Puffing Billy. For over 100 years, tourists have…

Read MoreBehind Closed Doors…

Whilst the restrictions around COVID-19 mean we aren’t currently able to open to the public, behind the scenes Puffing Billy’s workshops are a hive of activity, so an update seems…

Read MoreTesting An NG/G16!

For those that don’t subscribe to social media, you might have missed the multitude of excellent photos and videos over recent weeks, showing the Garratt undergoing testing by the railway’s…

Read MoreA New Whistle In The Hills!

Testing continues on the NG/G16, with work currently focused on testing and proving of boiler fittings and pipework; injectors, pressure gauge and water gauges, blower, safety valves and whistle have…

Read MoreFire In The Hole!

That’s right, your eyes don’t deceive you! A project which has been over 20 years in the making, with many challenges, and with so many hours of work behind the…

Read MoreNG/G16 – A Quick Update

As the design and manufacture stage of the project is virtually complete, and the workshop staff complete the finishing touches, here’s what we’ve been up to since last time: The…

Read More