Whilst the restrictions around COVID-19 mean we aren’t currently able to open to the public, behind the scenes Puffing Billy’s workshops are a hive of activity, so an update seems timely.

With a new cleaning regime and responsible social distancing measures in place, staff are progressing a number of projects to ensure the railway is in the best shape to hit the ground running when restrictions are eased and our little train can resume running through the Dandenongs once more.

Up at Emerald, the Carriage & Wagon team are flat out working through maintenance and upgrades to our fleet of historic carriages. Four of our new NBH class carriages have now been completed, and the remaining four are on site, having had all the mechanical fitting work completed which is necessary prior to body fit out.

With a number of carriages beginning to show signs of wear and tear, a program to catch up on carriage repaints has been started. Officially termed ‘Rebuild & Repaints”, this job involves repair or replacement of any rotten or damaged timbers, rectification of any metal corrosion, repair of seat upholstery and weather blinds, as well as a full repaint, internal and external.

The first carriage getting ‘the treatment’ is 10 NBH, which was suffering from extensive rot in one of the side panels. This has been completely replaced using the high-quality marine ply used on all our carriages, and the screws replaced with stainless steel to prevent further corrosion.

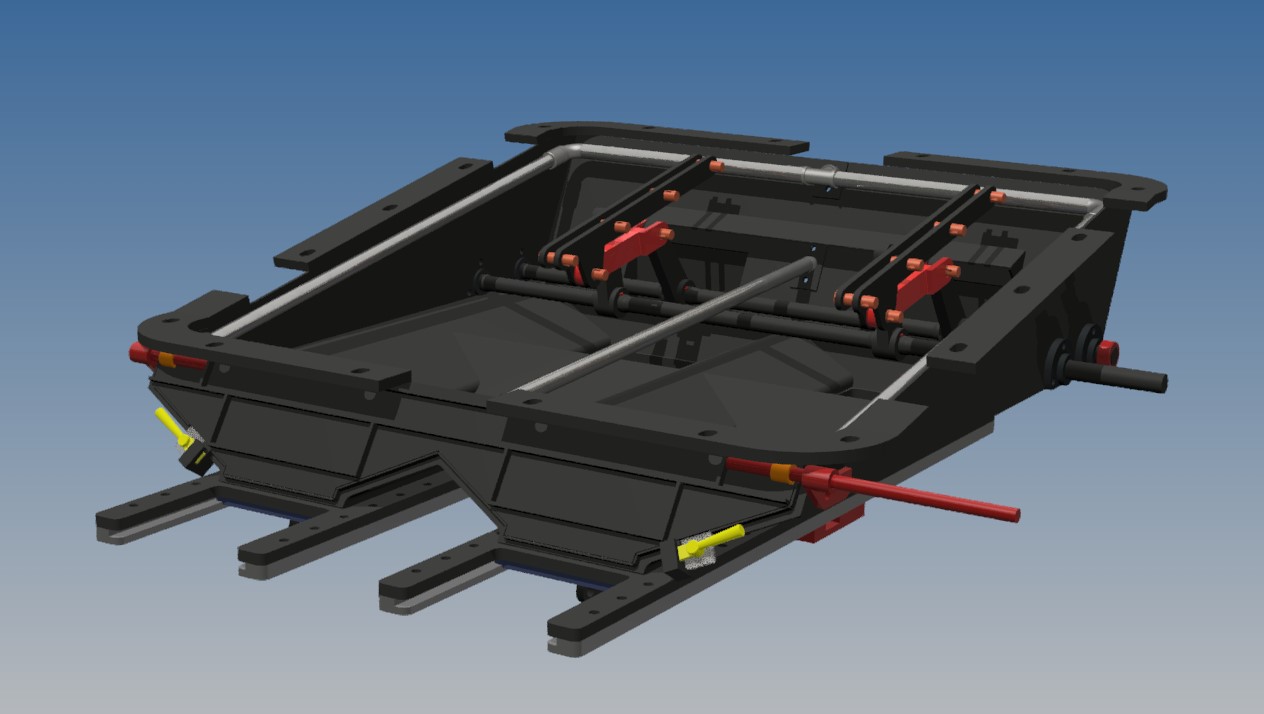

At the locomotive workshop in Belgrave, frames for our four new NBHC type carriages have been delivered and lowered onto their bogies. Above, the last carriage frame arrives from the fabrication company, Tradeweld in Traralgon.

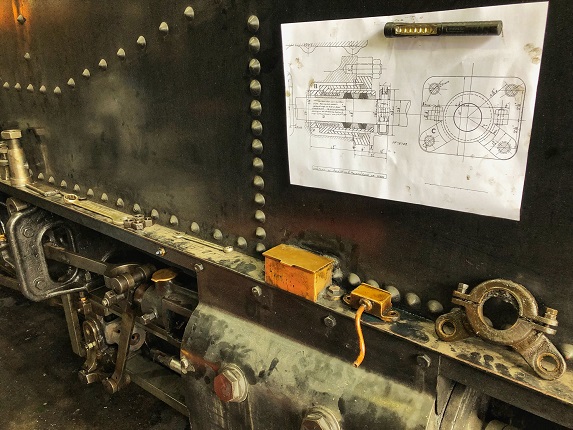

Below, fitting work to the couplers, drawgear and brake system is underway in the workshop, in preparation for their transfer to Emerald for fit-out and painting.

Also at Belgrave, progress is evident on two major locomotive projects.

12A is undergoing a ‘D’ exam, with all wheelsets, pony trucks, motion, valve-gear and brake rigging dismantled. With most pins and bushes replaced, and the tyres having been re-profiled, the wheelsets and pony trucks are being reassembled. All the motion and valve-gear, brake rigging, pony truck components and wheelsets have been Magnetic-Particle tested to ensure there are no cracks in any of the components.

6A has been stripped and assessed ahead of a major rebuild, and there will be more on this project in an upcoming post.

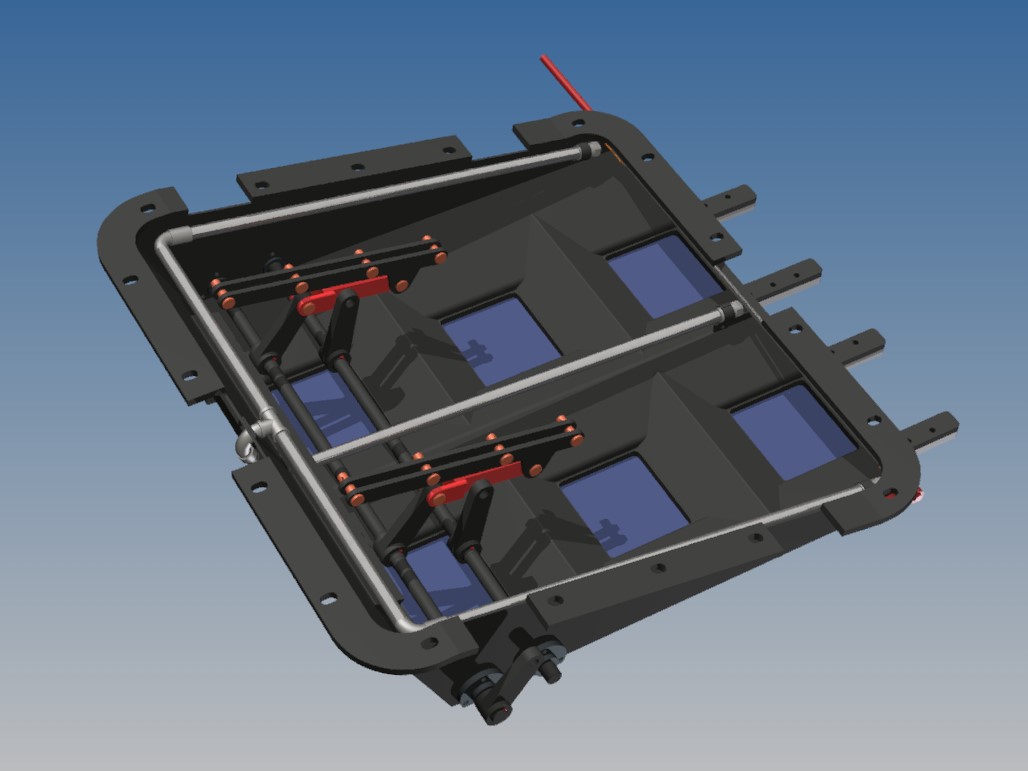

In addition, design and planning is underway to enable us to rectify of some issues identified during commissioning of NG/G16 129. In particular, a revised ash pan design is being developed to make it more operator-friendly.