With 4 fitters now employed full time on the restoration of NG/G16 129, momentum is gathering and what has, until recently, resembled a large kit of parts, is slowly coming together as this latest progress report shows.

The piston valves have been assembled and trial fitted into the valve chests (above).

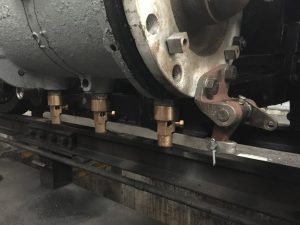

Following overhaul, the 8 Bypass valves have now been painted and fitted to the cylinder blocks.

Cylinder drain cocks, operating cylinders and all their associated operating linkages have now been completed and mounted to the engine units.

The crossheads are now complete, including re-metalling and machining of the slippers, and fitting of side liners, and have been installed onto the slidebars.

Much of the valvegear has been reconditioned (above and below), with holes centres being restored to as-built dimensions.

Additionally, a large number of new bushes and pins have been manufactured, and these are awaiting case-hardening prior to assembly.

Lifting arms have been fitted to the weighshafts, and these have been fitted to the engine units following final alignment of the bearing brackets.

Above, the side rod bushes have been whitemetalled, following which they underwent final machining and have now been fitted to the rods. Retaining bolts and all the pin feed lubrication components are also to hand, ready for final assembly.

Work has begun on the lubrication system, including overhaul of the oil feed check valves and pressure testing of the mechanical lubricator oil pumps.

The Injectors (above) have now been dismantled, cleaned, overhauled as required, and re-assembled.

The profile cut plates for the running boards on the 2 engine units have arrived, and are ready to have holes drilled for fitting. The 2 smaller, thicker plates will becoming mountings for the 2 mechanical lubricators.

The auxiliary reservoir has arrived from Britannia:Jahco and awaits painting (below) before it is mounted to the boiler cradle between the 2 main air reservoirs.