Work moves on apace with NG/G16 129, including the following tasks:

- Removal of boiler from the cradle to enable final installation of all the steam, exhaust and water pipework, as well as insulating and cladding the boiler.

- Superheaters and main steam pipes have been fitted in the smokebox (above and below).

- Work on the sanding gear; sandboxes, air sand traps and pipework.

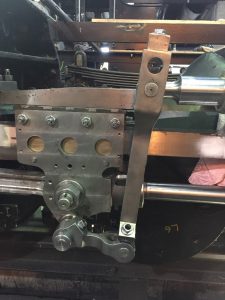

- Overhaul of cylinder and linkage for the rocking grate, including manufacture of new components as required.

- Refurbishment and manufacture of components for the lubrication system, including overhaul of the Wakefield Lubricator (above) and assessment of dividers, atomisers etc. for the lubrication lines (below).

- Manufacture and fitting of blowdown valve linkage.

- Riveting of the running boards to the boiler cradle, and grinding back of rivet heads.

- The manufacture of pins and bushes for the valvegear continues, with many parts trial fitted to the engine units.

- Installation of tank support timbers, engine unit footplates and lubricator mounting plates.

- Final assembly of steam and exhaust pipework on the engine units, including steam expansion joints.

- A custom-designed lifting bracket for the rear of the boiler has been fabricated and load tested, reducing the time and effort required to sling and balance the boiler when lifting.