Currently the workshops are preparing the machined parts for 6A’s wheel sets ahead of assembling at Inver Engineering in Altona. With all current wheel sets in the NA fleet comprising of a mixture of original and new parts, the 6A wheel sets will be made entirely new.

Pictured here we see the finished crank pins for the driven and coupled wheel sets. These were all turned from stock then ground in the lathe with tool post grinder.

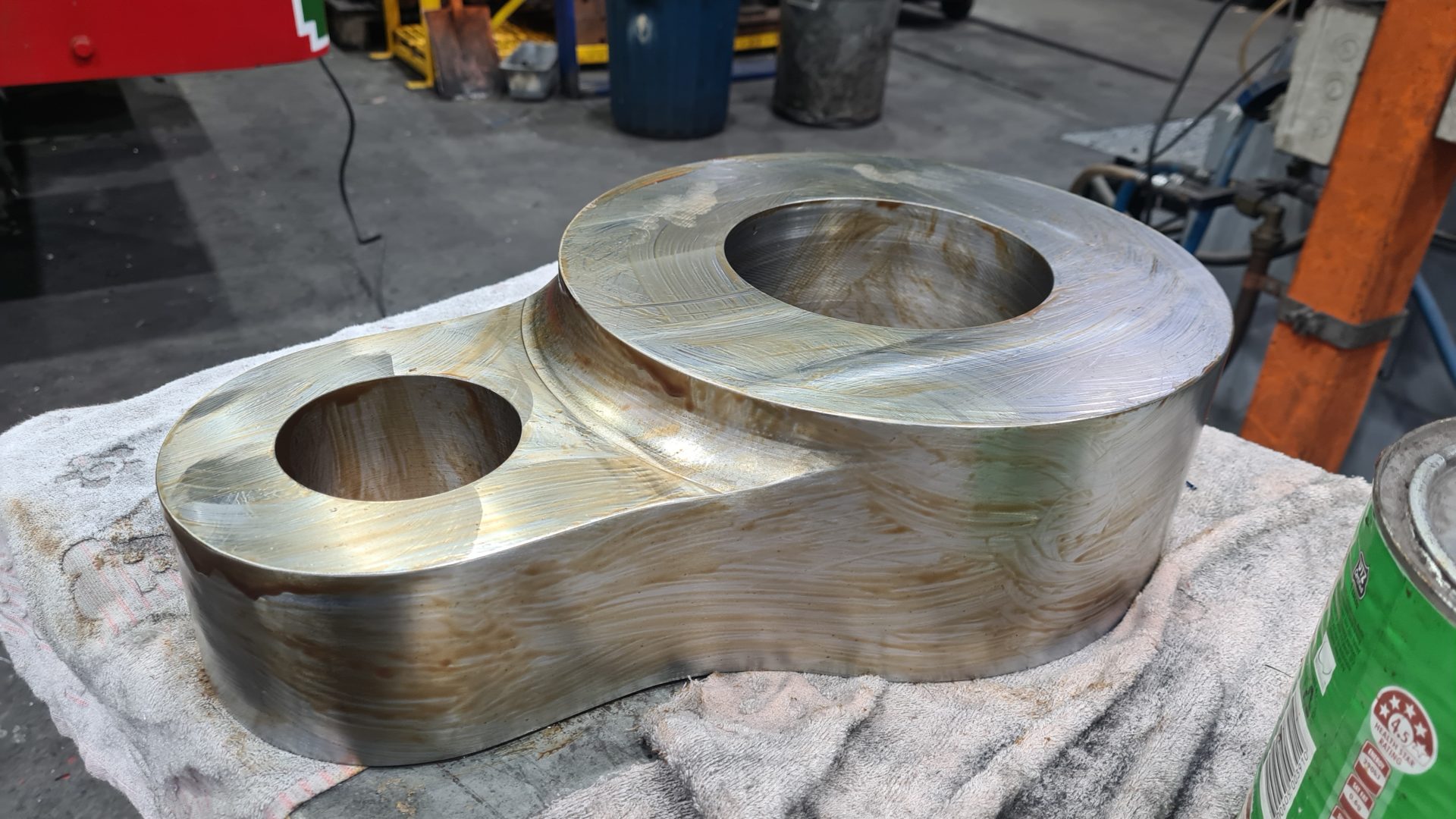

Also pictured is a pallet of oxy-cut heavy plate in the basic shapes of the crank webs for the locomotive. These are faced and profiled on the milling machine with the aid of a rotary table with a power feed. Large engine parts, especially like crank webs, have not been produced since the locomotives were originally built, making these the first of a host newly manufactured parts to replace the worn originals.