Following a noticeable drop-off in performance during last years final FETs (Footplate Experience Trains), 861 was transferred to the locomotive workshops at Belgrave to try and ascertain what was causing this decline.

One of the main issues apparent from a detailed inspection was the poor state of the exhaust system (above), which hadn’t been designed solidly enough to cope with the engines workload over recent years, and was now certainly doing nothing for draughting efficiency.

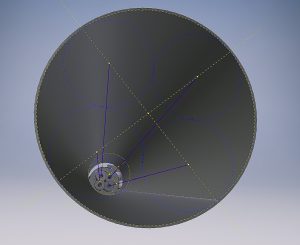

Using our 3D CAD software, a new exhaust manifold, 4-nozzle blast pipe and replacement chimney liner were modelled and drawings produced. Above, a CAD view looking down the mixing chamber (chimney) with the multi-nozzle blast pipe visible at the bottom.

Raw materials were ordered and manufacture of components began. Above, the exhaust manifold, which combines the exhaust steam from the cylinders, is being fabricated from pipe and standard elbows, cut to suit.

The multi-nozzle blast pipe, complete with integral blower and air compressor exhaust nozzles, was fabricated from plate and bar stock, before being welded together by the boilermaker. Whilst this is not a Lempor exhaust, it has similar features, including a requirement for complex machining to manufacture the four nozzles and ensure they fit together perfectly.

The effectiveness of the spark arrestor was also known to be questionable so the arrangement was revised at the same time. Modifications to the smokebox, including a removable top section as fitted to the NA fleet, will facilitate greater accessibility. Above, with this plate removed, the table plate is visible with blast pipe in the center, and baffle plates tack-welded in position.

With the new manifold, blast pipe and spark arrestor installed and tested, the outcome is an engine that steams freely, maintains a much more stable firebed, whilst being much quieter at the same time.