Mention has been made previously of the need to manufacture more bogies for our rolling stock. Many are now approaching the end of their useful life, with frames and axleboxes being condemned after a lifetime of wear and tear.

The new rolling stock project involves the manufacture of 12 new carriages, and therefore 24 bogies, onto which we have added a further 8 to ensure we do have spares available as old ones are progressively withdrawn from active duty.

This however is still some time away, and we needed a more immediate solution. With a critical shortage of serviceable axleboxes, attention soon turned to the bogies sitting under off-register rolling stock. These would be able to provide our immediate requirements, provided we could come up with a suitable substitute, which didn’t involve rolling stock on stack of sleepers littering the railway.

After sketching up a few ideas, the engineering office produced a concept for a quick, cheap and easy substitute axlebox, which would be perfectly adequate to keep our off-register rolling stock portable, whilst freeing up valuable Fox bogie axleboxes.

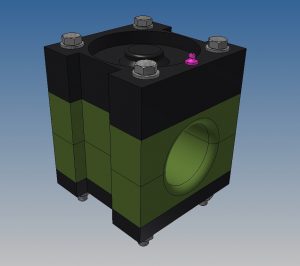

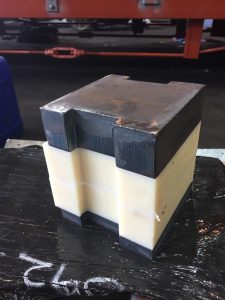

The design uses profile cut steel and nylon plates, with a minimum of machining, to replicate all the interfaces of the existing axlebox, including the horn slots, axle journal, and spring locating spigot.

Two profile cut nylon plates are sandwiched between two steel plates to the same profile, and a hole to receive the axle journal bored through the middle.

Two profile cut nylon plates are sandwiched between two steel plates to the same profile, and a hole to receive the axle journal bored through the middle.